Table of Contents

The Role of Enterprise Resource Planning (ERP) in Optimizing Supply Chain Management

In the dynamic landscape of modern business, the integration of Enterprise Resource Planning (ERP) systems with supply chain management has become a strategic imperative for companies aiming to streamline operations, enhance efficiency, and meet customer demands effectively. This article delves into the multifaceted role of ERP in supply chain management, exploring its benefits, key functionalities, and best practices for implementation.

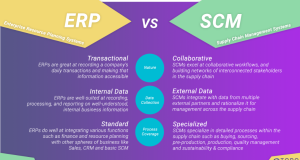

Understanding the Synergy: ERP and Supply Chain Management

Enterprise Resource Planning (ERP) systems act as a linchpin, seamlessly integrating crucial supply chain functions such as demand planning, procurement, manufacturing, and distribution. This integration empowers companies to navigate the complexities of the supply chain while optimizing costs and maintaining a competitive edge.

Benefits of ERP in Supply Chain Management

1. Improved Efficiency and Customer Retention

ERP systems contribute significantly to operational efficiency, allowing companies to respond swiftly to customer demands. The streamlined processes enhance customer satisfaction, fostering increased retention rates.

2. Automated Workflows and Reduced Overhead Costs

Automation is a hallmark of ERP systems. By automating various supply chain activities, companies experience reduced operational costs, minimized errors, and increased overall productivity.

3. Flexible Supply Chain Solutions

Leading ERP systems come equipped with modules that address key supply chain activities, offering flexibility in adapting to changing market dynamics. This adaptability is crucial for staying agile in a competitive business environment.

Key Functionalities of ERP in Supply Chain Management

1. Planning

ERP systems facilitate comprehensive planning, aligning production schedules with demand forecasts. This ensures optimal resource utilization and timely delivery of products.

2. Procurement and Inventory Management

Efficient procurement and inventory management are pivotal components of a robust supply chain. ERP systems provide real-time visibility into inventory levels, aiding in strategic decision-making.

3. Warehouse Management and Order Fulfillment

Warehouse operations and order fulfillment are streamlined through ERP, enhancing accuracy, reducing lead times, and improving overall customer satisfaction.

Selecting the Right ERP Solution

Choosing an ERP solution tailored to a company’s current and future needs is paramount. Functionality, scalability, and complexity must be carefully considered during the implementation phase. Here are some best practices:

1. Assess Functionality

Understand the specific needs of your supply chain and ensure the ERP system aligns with these requirements. Look for modules that cater to planning, procurement, inventory management, warehouse operations, and order fulfillment.

2. Scalability Matters

A scalable ERP solution grows with your business. Consider future expansion plans and choose a system that can seamlessly adapt to evolving demands.

3. Complexity Considerations

Evaluate the complexity of your supply chain operations. The chosen ERP system should offer the right level of sophistication without overwhelming your team.

Conclusion

In conclusion, the integration of ERP systems with supply chain management is a transformative step for businesses seeking operational excellence. From planning to order fulfillment, ERP enhances efficiency, reduces costs, and provides the flexibility needed in today’s fast-paced market.

FAQs

Q1: How does ERP improve supply chain efficiency?

A: ERP improves supply chain efficiency by automating workflows, providing real-time visibility into key activities, and facilitating comprehensive planning, procurement, and inventory management.

Q2: What factors should be considered when selecting an ERP solution?

A: Factors such as functionality, scalability, and complexity should be carefully considered. Assess the specific needs of your supply chain and choose a solution that aligns with both current and future requirements.

Q3: Can ERP systems adapt to changing market dynamics?

A: Yes, leading ERP systems come equipped with flexible modules that allow businesses to adapt to changing market dynamics, ensuring agility and competitiveness.

Q4: How does ERP contribute to customer retention?

A: ERP enhances customer retention by improving operational efficiency, reducing lead times, and ensuring timely delivery of products, thereby increasing overall customer satisfaction.

Q5: Is it necessary to automate supply chain activities with ERP?

A: Yes, automating supply chain activities with ERP reduces operational costs, minimizes errors, and increases overall productivity, making it a crucial aspect of modern business operations.